When is a Wurster system used?

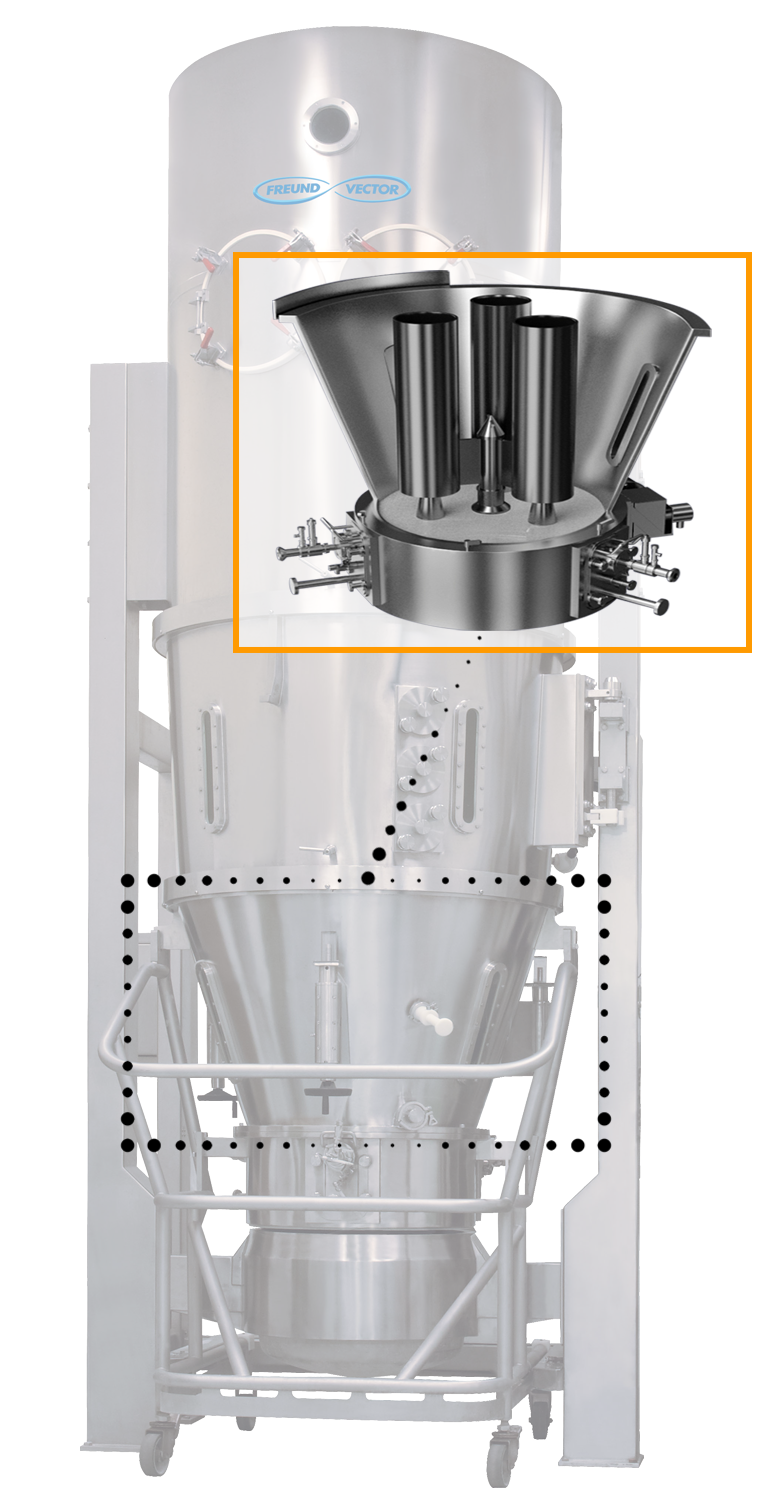

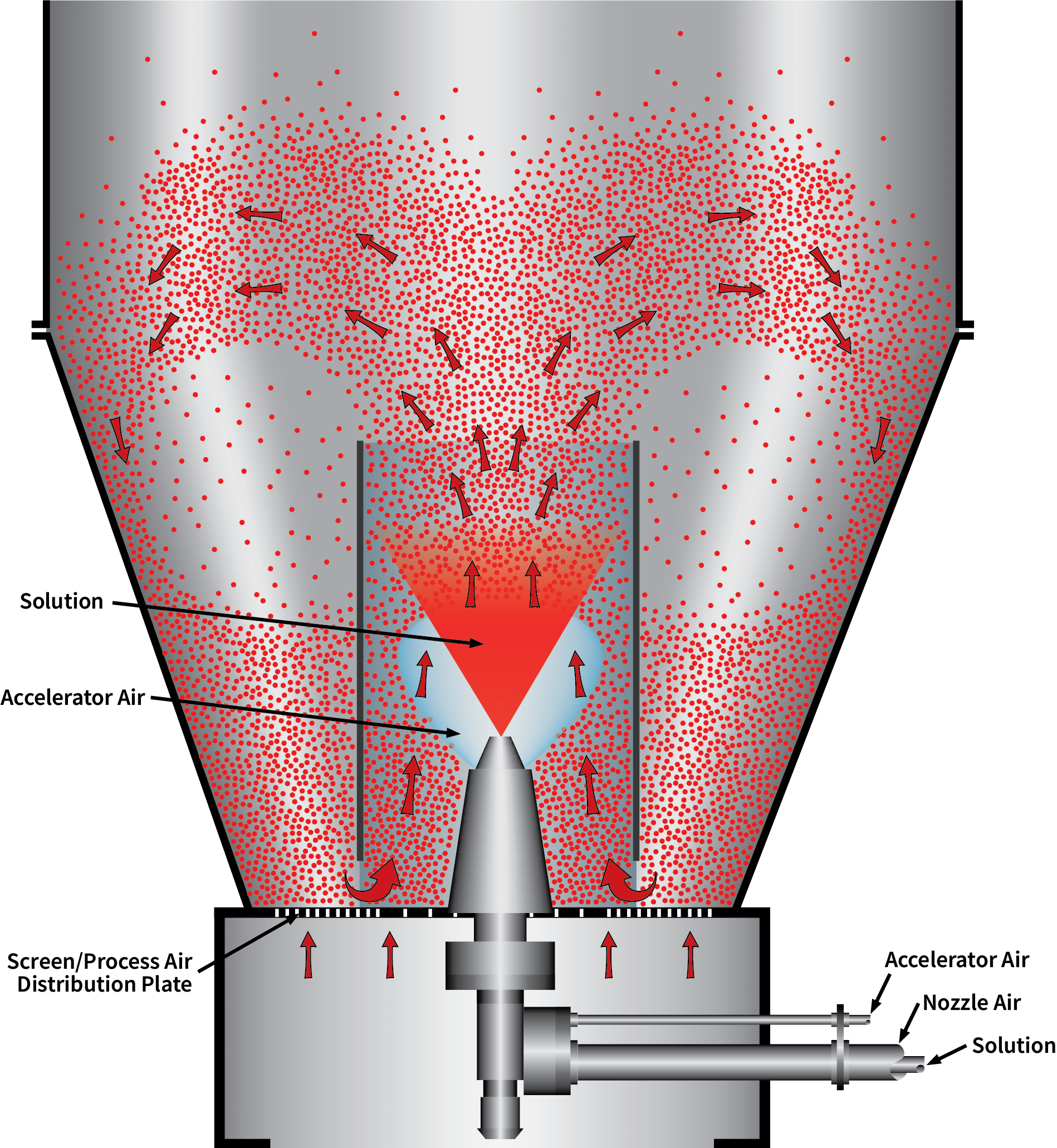

The Wurster coating system is ideally suited for the coating of particles ranging from fine powders (~10 micron) up to small pellets (2-3 mm). It consists of a processing insert that is placed inside a fluid bed processor.

What is the Wurster Accelerator?

Freund-Vector’s patented Wurster Accelerator System provides the fastest possible spray rates for Wurster coating processes. Compressed air diverts product away from the spray nozzle tip, optimizing product movement through the spray zone and minimizing agglomeration.

What are the results?

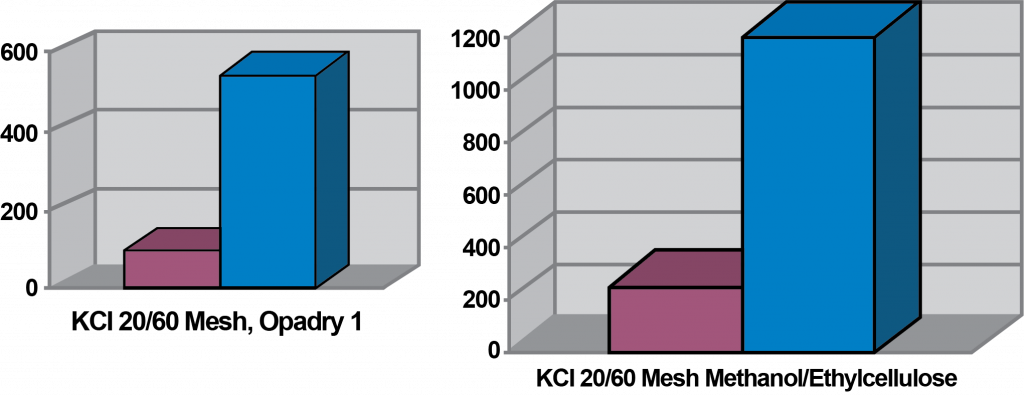

Diverting the particles around the spray nozzle allows for a much faster spray rate to be achieved, lowering process times and decreasing the attrition normally found in longer Wurster coating processes. In the case study below, improvements of spray rate up to 600% were achieved when using the Wurster Accelerator coating system.