Is there a solution that could take an existing Wurster process and transfer it to a conical rotor to reduce the processing time and pieces of equipment required to complete the process? Freund-Vector and Depomed collaborated on a study to determine this and the results showed Freund-Vector’s GRANUREX® GXR-35 is a viable solution.

The existing process consisted of multiple steps. First, a sugar/starch NP was loaded into a Wurster coater and a suspension of omeprazole was sprayed with an HPMC binder to create an omeprazole loaded bead. Those beads were then coated with a barrier and enteric coating. Following the polymer coating, the beads were placed into a top spray granulator and co-granulated with a cushioning agent to allow for tableting. In the rotor process, all the steps were completed using a single conical rotor, GRANUREX® GXR-35

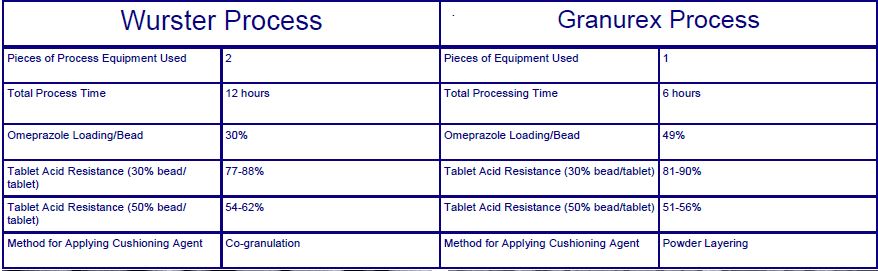

The results of this study showed that transferring the process from the Wurster coater and top spray fluid bed to the GXR rotor resulted in a more efficient, faster process that was completed in one machine without the need to transfer the product. The processing time was cut in half with fewer product handling steps and fewer pieces of equipment used. Below is an illustrative chart that shows the process results from this study.

To read or download this poster, Please click here.