Granurex Technology Integral to Novel Processing Technique

Freund-Vector’s GXR technology and Dow’s Ethocel™ HP allows customers to coat multiparticulates without the need for solvent or aqueous-based polymers. This new technology allows for improved productivity and shorter coating times while moving away from solvent-based polymers.

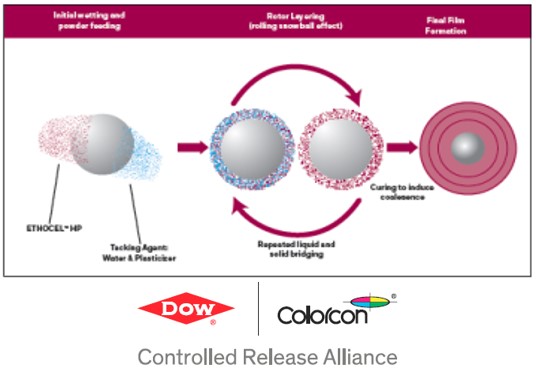

The dry powder laying process works by wetting the substrate with a plasticizer/water combination. The dry polymer is applied to the wet surface of the substrate and a liquid bridge occurs between the dry powder particles and the surface of the substrate. The wetting agent and dry powder are continually sprayed as the polymer layers are formed like a snowball rolling in snow. After sufficient drying, the dry power coated substrates are cured. Below is an illustration portraying the dry powder coating process.

The ‘rolling snowball effect’ is illustrated in the picture above. Watch the process by clicking on this link: Granurex Powder Coating Processing Video .

The advantages of processing Ethocel™ HP on a GXR insert are as follows:

- Solvent free

- Reduces manufacturing costs

- Increases productivity

- Reduces equipment needs (combines API layering and polymer layering)

To read or download this poster, Please click here.

We look forward to discussing how Freund-Vector’s GXR Technology can assist you with developing and manufacturing pharmaceutical products.