With fluid bed systems, safety always must be considered as the highest priority. Due to static discharge, there always remains the risk of an explosive environment within the fluid bed chamber. The safety risk is heightened when solvents are used as the binding solution.

There are two standard design methods to safely deal with this explosive potential: 12 bar containment and vented. Both are equally safe when correctly applied. Depending on the application, one design method may have an advantage over the other.

12 Bar Containment

The philosophy behind 12 bar containment is that the pressure wave prior to an explosion (also known as deflagration) is contained. Since the deflagration is entirely contained and not allowed to expand, the subsequent explosion is quenched. The biggest concern implementing this design is ensuring that ALL components connected to the fluid bed system are rated at 12 bar over pressure. Any component not rated at 12 bar may result in the deflagration escaping in an uncontrolled manner…thus leading to an explosion.

In terms of design, Freund-Vector is the only manufacturer to use non-inflatable seals for 12 bar containment. The seals are made from a high grade silicone instead of commonly used air seals. The Freund-Vector seal is easier to install, can’t be punctured, last longer, and is more readily available when compared to the commonly used inflatable seals.

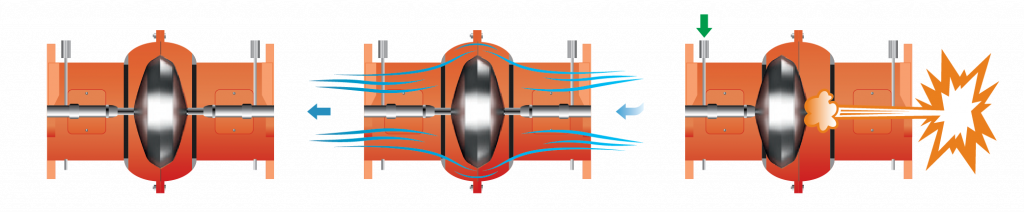

To ensure the pressure is contained within the ductwork, passive isolation valves are mounted in the inlet and exhaust ducts to help contain the flames and pressure waves.

All Freund-Vector 12 bar fluid beds are hydrostatically tested per VDI-2263 standard. The hydrostatic test consists of filling the fluid bed tower entirely with water, then pressurizing the water at levels defined by the VDI standard.

Vented

With this philosophy, the idea is to move the pressure wave as far away from personnel as quickly as possible. This is typically done through an explosion vent. The pressure wave is allowed to expand in a controlled manner through the top of the fluid bed and through an explosion vent. When the explosion vent extends well beyond the exterior of the building, guiding the deflagration into the atmosphere – where it can resolve safely to personnel and facilities.

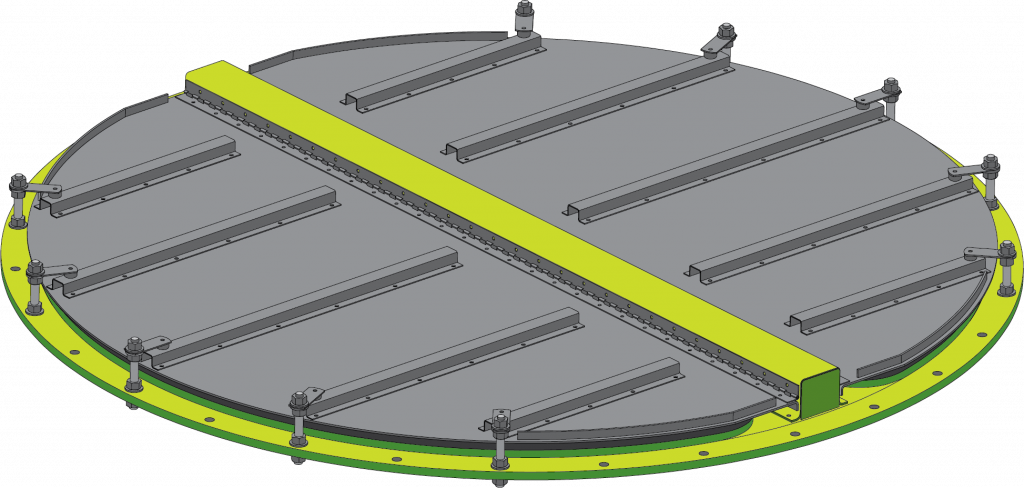

In terms of design, Freund-Vector uses fracture clamps and explosion relief panels on top the fluid bed and the exhaust ports to vent the explosion to an open, safe place.

Isolation valves in the exhaust is still necessary to ensure a pressure wave doesn’t migrate through the exhaust duct work. An inlet isolation valve can also be used, however, the product itself is usually used to stop the pressure wave from migrating to the inlet air handling system.

The primary concern with the vented design is the length of the explosion vent. Usually, there is a maximum limit of 6 meters. This length may decrease depending on the explosivity of the product being processed. So, in applications where the fluid bed may be placed on a ground floor or basement, there may not be enough overhead space to adequately consider a vent. In those situations, 12 bar design is the only way to proceed.

Freund-Vector can determine the best application based on the facility design and customer preference. Contact Freund-Vector today to have us review your fluid bed installation. We will gladly provide you with our feedback.