Patented Approach to Powder Coating

Freund-Vector conducted a study demonstrating the application of a powder coating to a multi-particulate pellet utilizing Freund-Vector’s patented Wurster Accelerator system. The results were so novel, unique and successful, Freund-Vector has called this new process our: “Wurster Accelerator 2” system.

Freund-Vector has just received notification of a US patent for this processing method.

A key element of the original Wurster Accelerator system was to use compressed air to divert particles away from the spray zone, allowing for an increased spray rate.

In a study presented at the 2016 AAPS show, Freund-Vector successfully introduced a powder flow within the diverting airflow. The study, entitled “A Novel Method for Introducing Dry Powder Directly into the Spray Zone of a Bottom Spray Wurster Coating Process”, added glidants (in powder form via a powder feeder ) through the diverting air at the same time coating solution is applied through the spray nozzle.

Traditional Wurster systems require glidants (such as talc) to be incorporated directly into the coating solution, which leads to “settling” of the glidants out of solution. This causes numerous processing problems, such as gun plugging, line plugging, extended processing times and inefficient coatings.

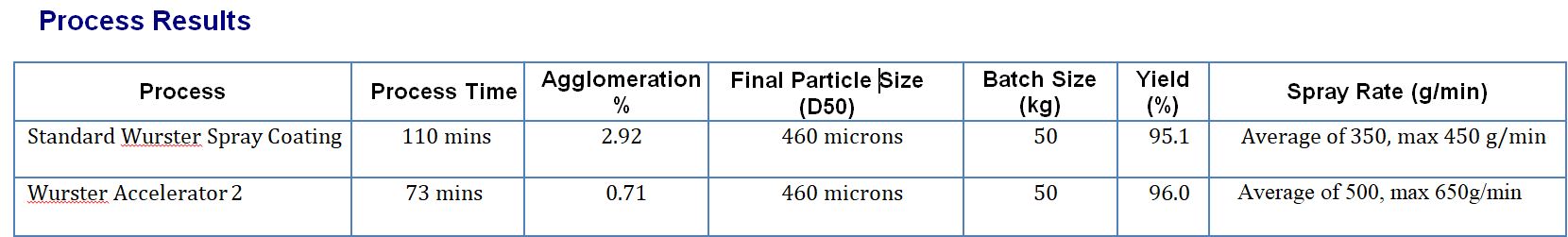

The conclusion of this study demonstrated that applying talc directly into the spray zone allowed for increased spray rates with reduced agglomeration during the coating process. By removing the glidant (talc) material out of the spray solution, the need to constantly stir the solution and the potential for line plugging or gun failure during the process was eliminated. See chart 1 below for study results.

To read and download this poster, Please click here.