Rotor Technology has been used to process multiparticulate pharmaceutical materials for many years, it’s an ideal situation for processing small particles. It provides excellent mixing, flowability with concurrent tangential spraying. However, Rotor technology does have its limitations in production use including; smaller capacities, ineffective drying and difficult to control airflow. That has all changed with the GRANUREX®. The equipment can offer larger batch sizes, better airflow control and efficiently introducing larger amounts of drying air into the system.

These advantages have eliminated many issues that plagued flat rotors and have allowed conical rotor technology to perform as a one-pot system for processing particles. When paired with a powder delivery system, conical rotor technology is the fastest, most efficient way to apply dry coatings of API and polymer coatings to small particles.

The GRANUREX® (GXR), Freund-Vectors patented conical rotor system is the most powerful pellet/powder processor available in the marketplace today. The GRANUREX® is a processing insert that fits within a VFC FLO-COATER® fluid bed systems ranging from 1.5L (lab size) all the way to 370L (production size). There are four (4) primary applications that can be performed by the GRANUREX®: Spherical Granulation, Powder Layering, Dry Polymer Layering and Solution/Suspension Coating.

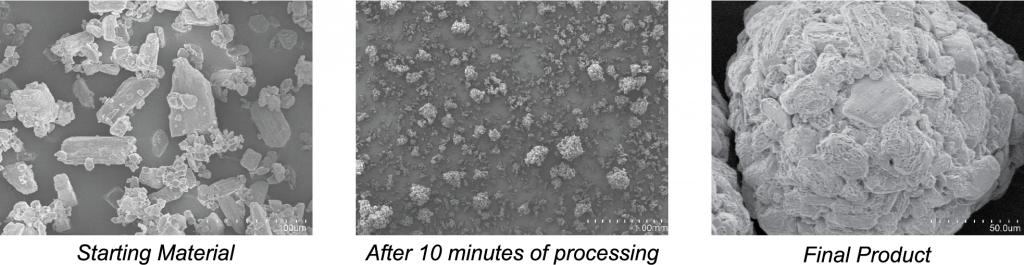

Spherical Granulation: Starting with a micronized API in the conical rotor, a binder solution is sprayed onto the powder to form granules. The spinning rotor imparts force onto the powder, forming a spherically-shaped granule. Spherical granulation requires very low airflows compared to top spray granulation. Final particle size is determined by spray rate, atomization pressure, and temperature; sphericity is determined by rotor speed.

Other advantages of the Spherical Granulation

- Able to create a granule with a very high API (90%+) content

- Granules are more spherical and suitable for post process coating

- Granules are typically 100-300 microns in size, ideal for ODT applications

- Achieves excellent content uniformity, even in very low dose formulations

Case Study Example: Spheronization of Ibuprofen

Starting Material Characteristics

- Powder: Ibuprofen

- Shape: Crystalline

- Size: 10-40 microns

- Density: 0.36 g/cc

- Flowability: Very Poor

Finished Material Characteristics

- Powder: Ibuprofen

- Shape: Spherical

- Size: 250 microns

- Density: 0.59 g/cc

- Flowability: Very Good

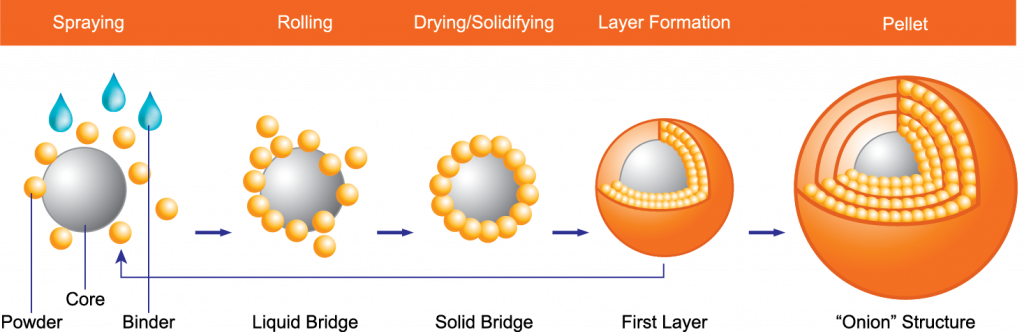

Powder Layering: It all begins with a core material; such as sugar, starch or a Microcrystalline Cellulose (MCC) sphere. The API is dispersed via powder feeder. The API should be micronized or very finely divided, ideally with an averaged particle size less than 30 microns. With the feeder dispensing the powder, the spray gun applies solution that binds the active to the outer surface of the core material. Applying the powder in dry form significantly reduces processing time because the API in applied at 100 percent of its solid weight instead of the 10-30 percent solid weight of a solution or suspension. With proper balance between the powder feed rate and the solution spray, the GRANUREX® produces a coating with precise API levels for a perfect particle size.

Other advantages of the Powder Layering

- Saves time over solution/suspension coating by adding active in powder form rather than by dissolving or suspending into a liquid and spraying

- Able to achieve up to 95% (over 500% weight gains) coating in a short time

- Ability to create a multi-layer bead with multiple actives in the same bead

- Reduces or eliminates the use of organic solvents

- Able to utilize several core materials, ranging in size from 150 microns to 1 cm in size

- Can utilize either inert (sugar sphere, mcc sphere) or API core

- Starting core material does not need to be round, but resulting coated particles will be round

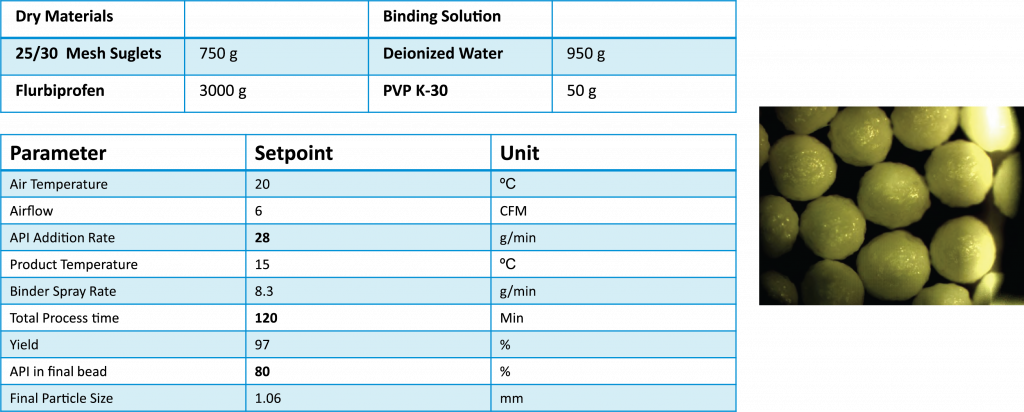

Case Study Example: Powder Layering of Flurbiprofen

Goal: To create a finished bead with 80% API loading

- 80% API loading (400% weight gain) achieved in 2 hours, entirely with an aqueous system.

- Doing the same process in a Wurster column @ a 20% solution would have taken 5 hours and used 15 kg of organic solvent.

Dry Polymer Layering: It’s the same process as active powder layering, except the powder feeder is filled with a polymer coating material instead of an API. A plasticizer solution is used to bind and plasticize the polymer to the outside of the core.

Advantages of the Dry Polymer Layering

- Ability to create a multi-layer bead with multiple actives in the same bead

- Reduces or eliminates the use of organic solvents

- Very low agglomeration, even when coating very small particles, ideal for taste masking.

- High processing yields and coating uniformity

- Low attrition, capable of coating friable particles that would erode in a Wurster

- Similar film quality to that of “sprayed on” films

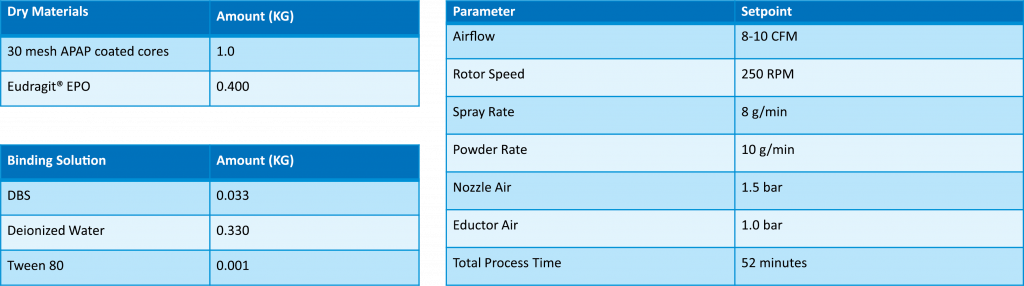

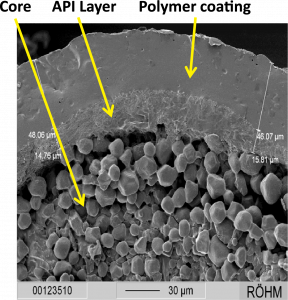

Case Study Example: Powder Layering Eudragit® E PO (Joint study with Evonik)

Goal: Achieve a completely taste-masked particle via a dry powder layering process using Eudragit® E PO.

- Taste masking was determined by having a panel of 7 volunteers place 300 mg of coated pellets on the tongue for a period of 1 minute.

Results

- A 40% E PO coating applied in 52 minutes

- 97% efficiency of polymer application

- Clear evidence of a coalesced film

- Complete taste masking was accomplished at coating levels of 5% or higher

- Complete drug release within 5 minutes in pH 1.2 media

- No organic solvents were used

Solution/Suspension Coating: Spray coating in a traditional rotor, the API or Polymer is dissolved or suspended into a liquid and sprayed onto a multiparticulate core. However, the GRANUREX® allows glidants such as a talc to be added as dry powders via a feeder system. This eliminates solids from the solution, which increases spray rates and minimizes clogs in the spray gun and solution line.

Other advantages of the Solution/Suspension Coating

- Very high coating uniformity and very high yields are possible

- Higher Spray Rates

- Excellent film quality and dissolution results

- As final step in some powder layering and spherical granulation processes

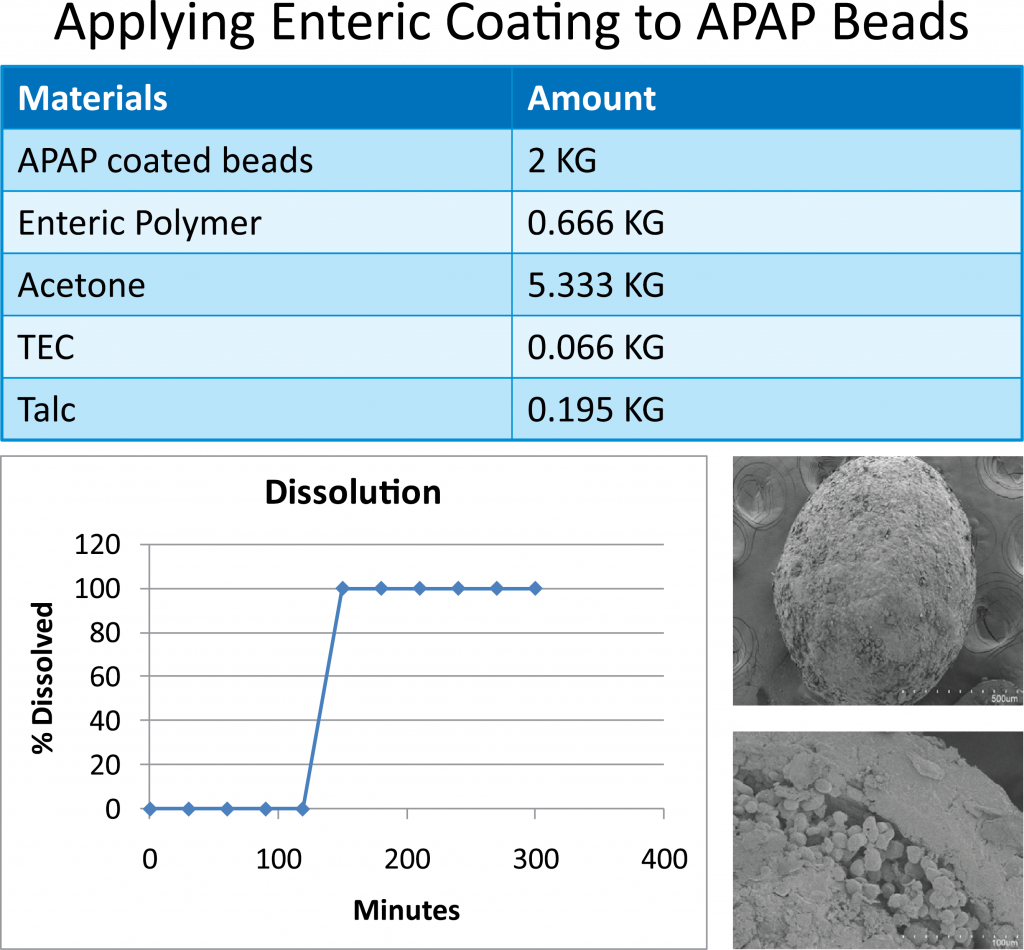

Case Study Example: Applying Enteric coating to APAP beads

- Talc was applied in dry form via the powder feeder

- Beads were coated to a 25% coating level

In Conclusion, the examples demonstrate that GRANUREX® processing provides significant processing advantages to today’s conventional coating methods. The key advantage(s) of the conical rotor in each of the study’s include; shorter processing times, fewer materials, higher yields, higher content uniformity, and increased productivity.

If you would like to learn more about the GRANUREX®, please visit our technology page or product page.