Freund-Vector’s Process Scientists conducted a study to determine what happens to particle size and shape when different binder activations are used with high-shear granulation processes. This study was done with immediate release (IR) and controlled release (CR) formulations using Freund-Vector’s GMX-25 GRANUMEIST®.

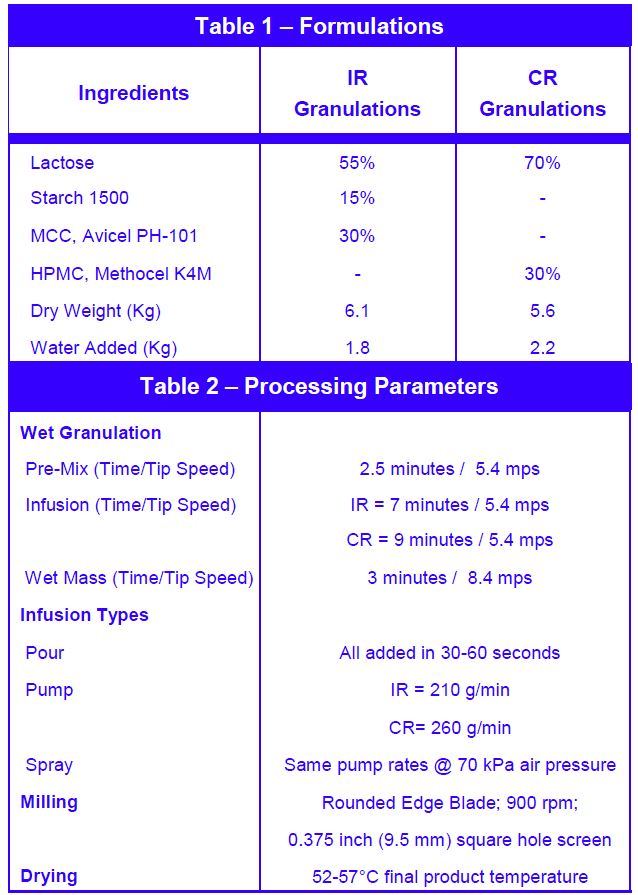

Immediate release (IR) and controlled release (CR) formulations were granulated in a 25-liter high-shear mixer (GMX-25, Vector Corporation). Formulation and process parameters are listed in Tables 1 and 2.

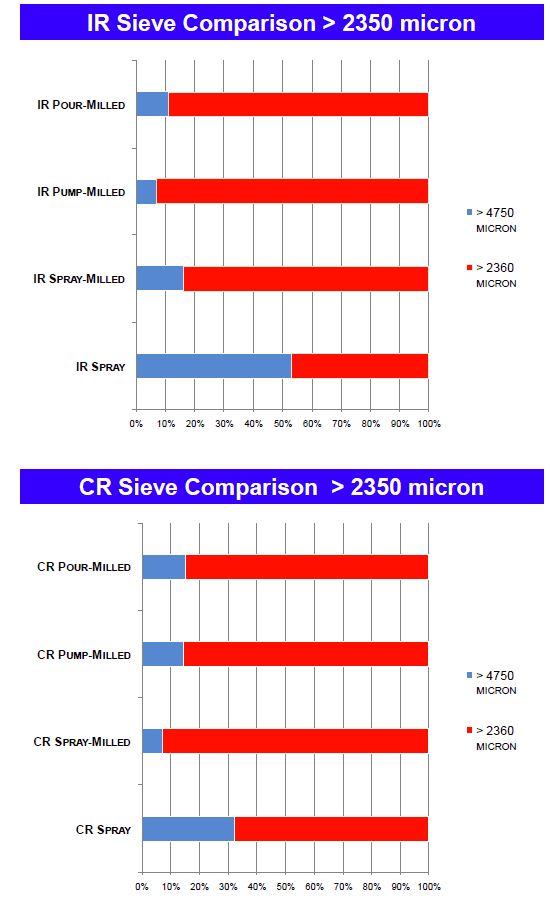

Freund-Vector’s Process Scientists were able to conclude that the means of adding binder will have differing degrees of effects on particle size and shape depending on the type of formulation used for high-shear granulations. Below is an illustration of the comparison between immediate release (IR) and controlled release (CR) sieve.

Freund-Vector’s GMX-25 GRANUMEIST® Top Drive Laboratory High Shear Granulator/Mixer is designed specifically for the critical process development phase. Its top drive design allows for easy cleaning and maintenance, faster processing times, and superior user safety. Engineered with the end user in mind, the GMX-25 is the ideal solution to your laboratory scale high-shear granulation processes.

To read or download this poster, Please click here.