Novel Processing Technique Using Granurex

GRANUREX® is a one-pot patented conical rotor insert that will fit within a VFC FLO-COATER® fluid bed system. There are four (4) primary applications that can be performed by the GRANUREX®: Spherical Granulation, Powder Layering, Dry Polymer Layering and Solution/Suspension Coating.

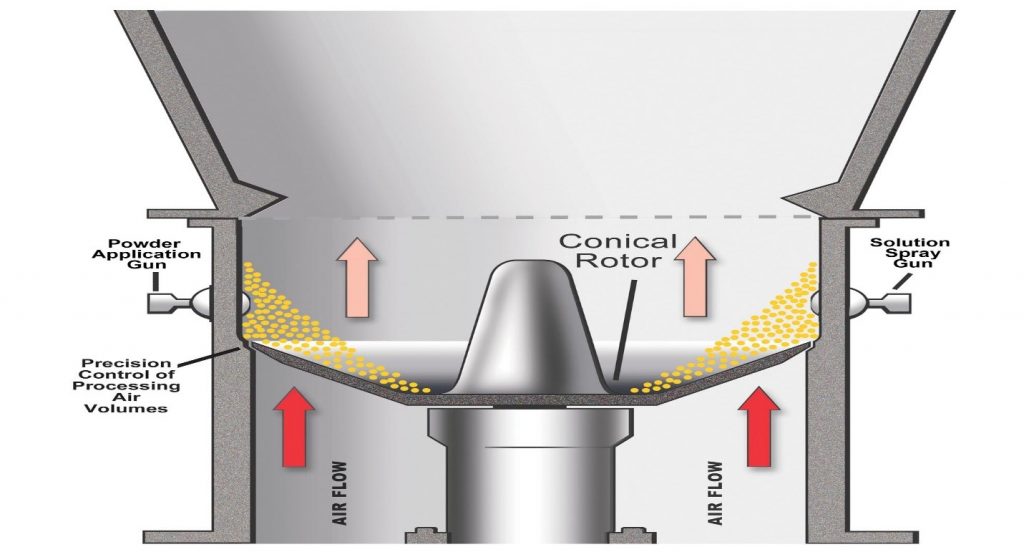

GXR’s dry powder layering starts with a core material, sugar, starch or Microcrystalline Cellulose (MCC) sphere. The active drug is fed into the powder application gun. The binder solution binds the active powder to the outside of the core material and the powder begins to coat the core. Below is an illustration of the dry powder layering process.

Some advantages of the GXR are:

- Up to 99% Process Efficiencies

- Time Savings of 50-400% Over Traditional Solution Drug Layering

- Fine Particle Processing

- Superior Product Uniformity

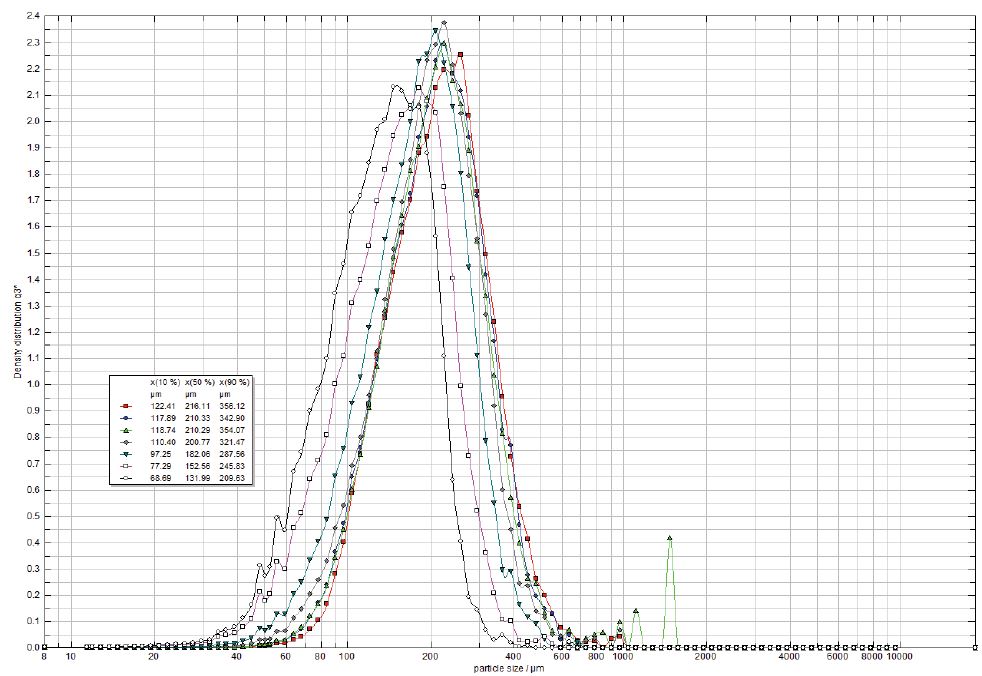

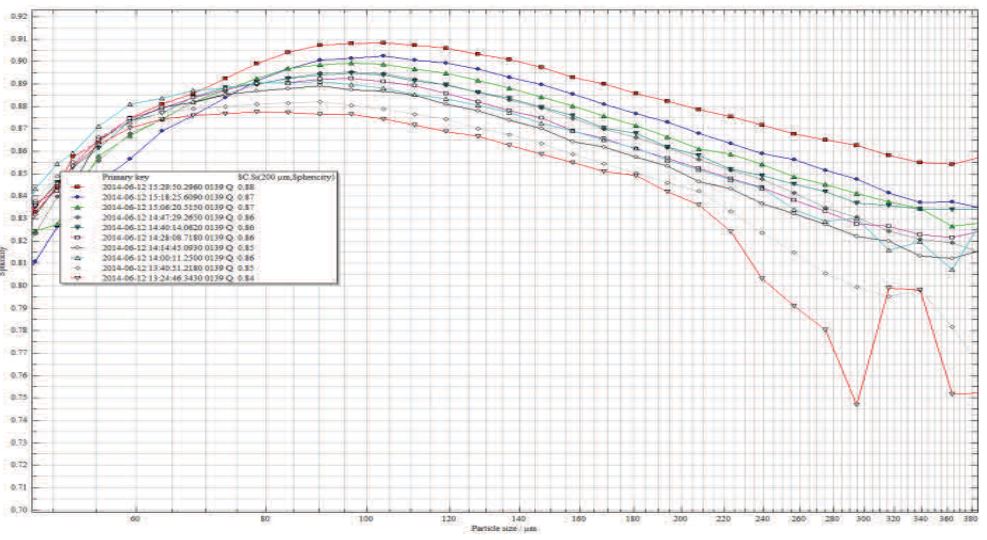

- Narrow Particle Size Distribution

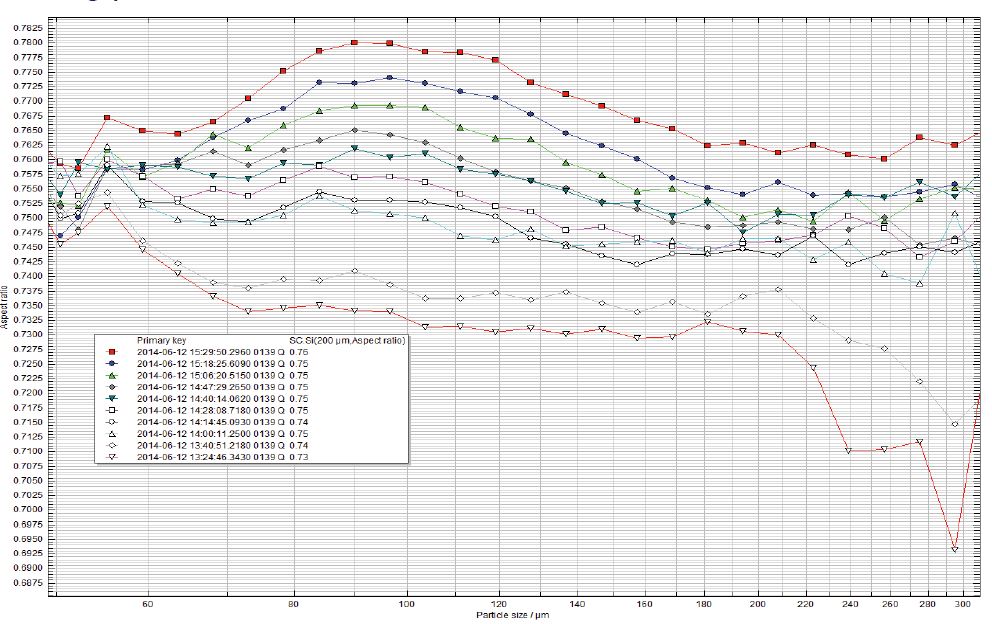

- Spherical Particles

- Multi Layering of Particulates

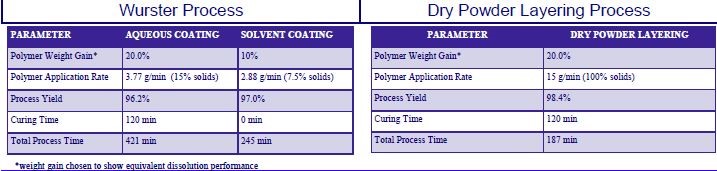

Let’s review a few case studies that illustrate the advantages of GRANUREX® (GXR)’s output:

Case study #1:

Case study #2:

To learn more about Freund-Vector’s GRANUREX® Insert, visit our Technology page.