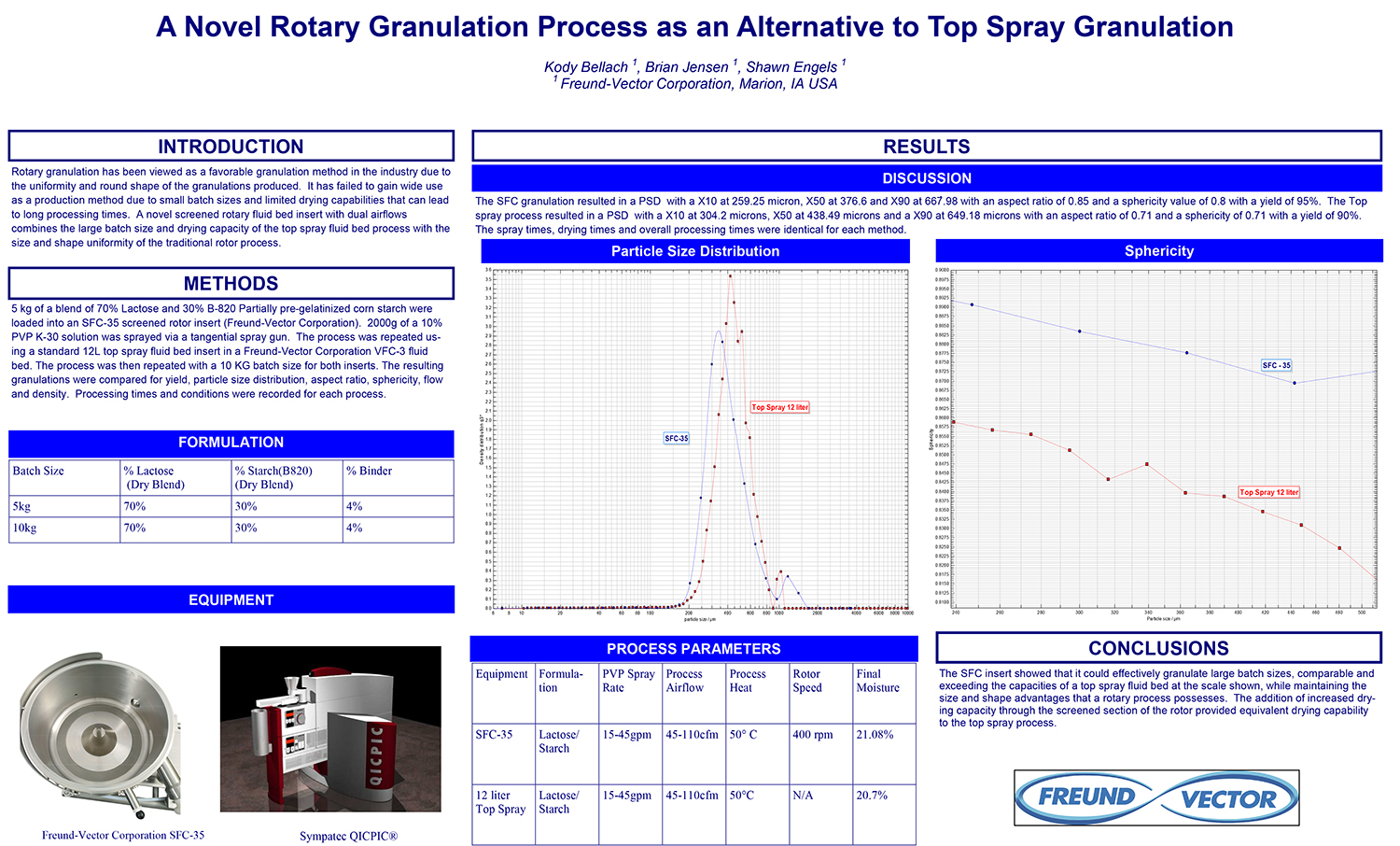

Novel Rotary Granulation Process (SFC) as an Alternative to Top Spray Granulation

Rotary granulation has been viewed as a favorable granulation method in the industry due to the uniformity and round shape of the granulations produced. It has failed to gain wide use as a production method due to small batch sizes and limited drying capabilities that can lead to long processing times. A novel screened rotary fluid bed insert with dual airflows combines the large batch size and drying capacity of the top spray fluid bed process with the size and shape uniformity of the traditional rotor process.