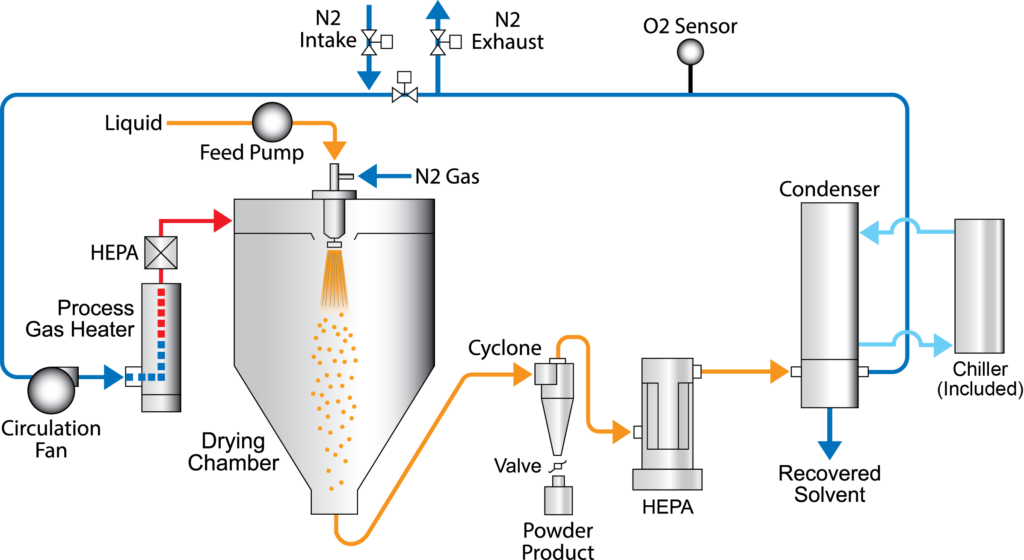

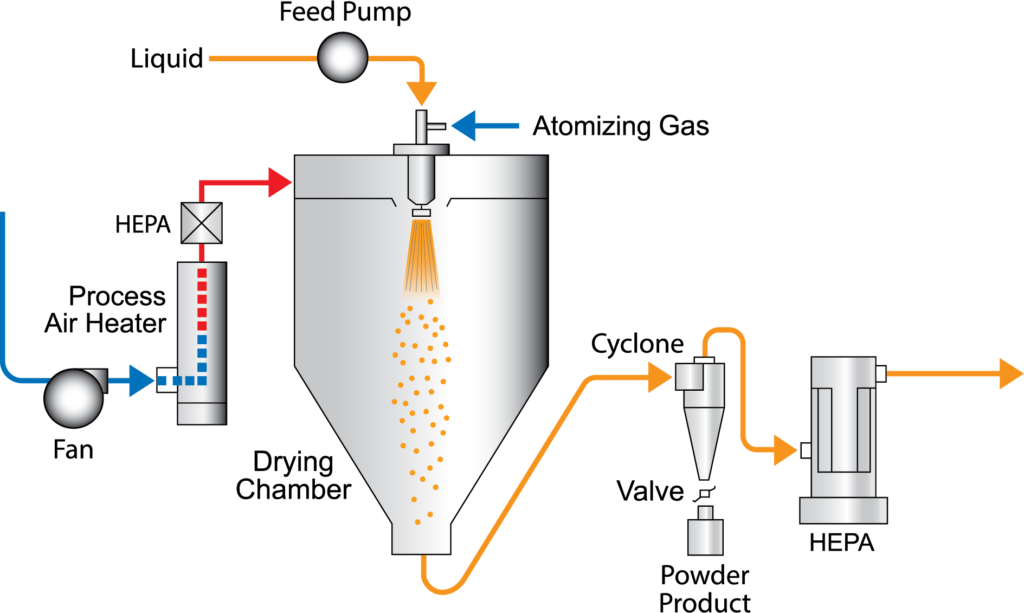

Spray drying is a method for producing a dry powder directly from a solution or slurry. In a continuous process, the liquid feedstock is dispersed as a mist of fine droplets into a stream of hot drying gas, all within a cylindrical drying chamber. In aqueous processes, the drying gas is typically air. For solutions composed of flammable solvents such as ethanol and acetone, the inert drying gas is nitrogen and the system operated in a closed cycle as illustrated below. In addition, an inert closed cycle is also useful for drying chemical and biologic materials that are sensitive to oxygen. Because the kinetics of drying are so rapid, materials are dried in a fraction of a second which helps to make the process viable for thermal sensitive materials such as foods, extracts and other organic substances.

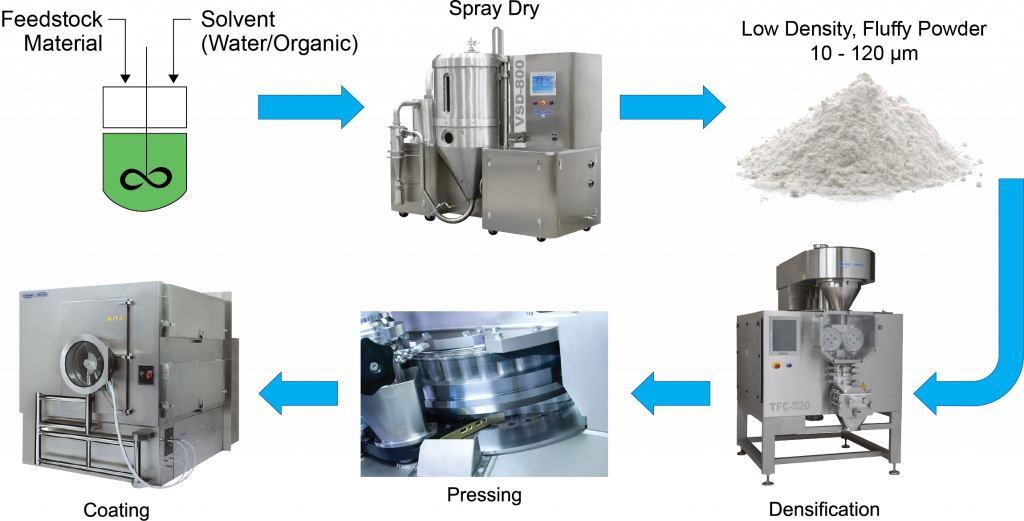

Process Example for Drug Products