Freund-Vector and Dow Chemical conducted a study of spray coatings of ethylecllulose for controlled release on multi-particulate dosage forms. Long process times, need for organic solvent capabilities and particulate agglomeration are some challenges associated with this dosage form. This study highlights the advantages of a rotor dry powder layering process in overcoming these deficiencies by comparing performance, productivity and cost to solvent-based Wurster coating and aqueous-based Wurster coating.

Using a conical rotor, GRANUREX® GXR-35, the drug layered beads were powder layered with micronized ethylcellulose (ETHOCEL™ EXP-1). For comparison, APAP drug layered beads were coated in a bottom spray fluid bed, VFC-Lab 3 8” Wurster with ethylcellulose (ETHOCEL™ STD 10 Premium).

Our conclusion shows that the rotor dry powder layering process demonstrated controlled release coatings and was applied at rates 2-4 times faster than traditional spray coating systems. Additionally, the rotor dry powder layering process showed: a) eliminates organic solvent based formulations which help alleviate concerns around environmental health and safety considerations and b) eliminates aqueous based formulations which enable coatings to be applied to water sensitive ingredients.

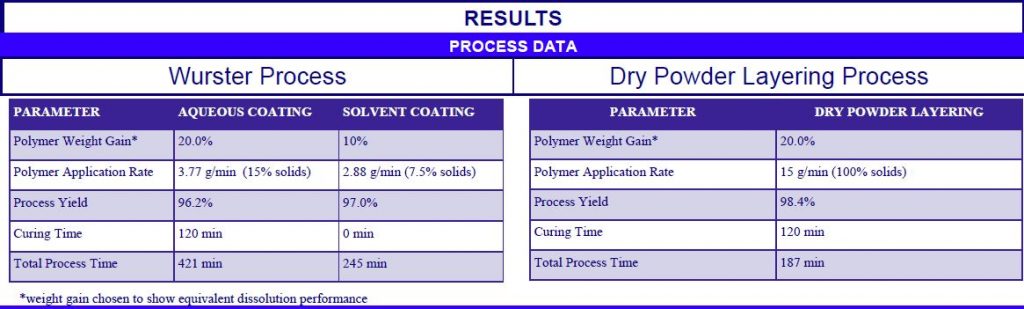

Below is an illustration that outlines the results of this study.

To read and download this poster, Please click here.

Visit Dow’s website showing ETHOCEL HP by clicking on this link.